Changing the Way Cars Are Built

Traditional auto manufacturing moves slowly. Creating new parts has always meant investing weeks or months into molds, tooling, and complex setups an expensive commitment for carmakers. If a design flopped or needed adjustments, the whole process had to start over. Not exactly nimble.

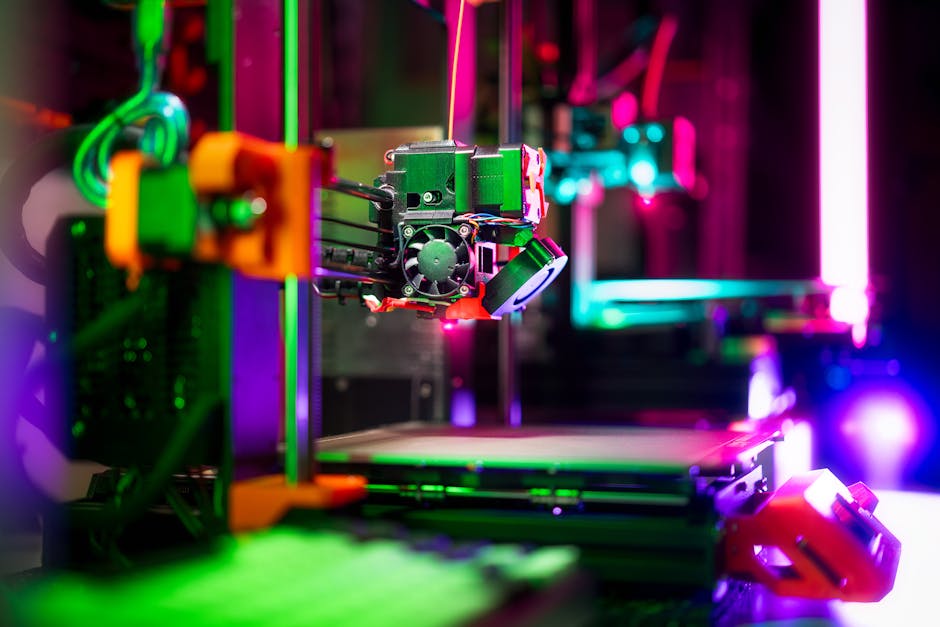

3D printing flips that model on its head. Now, engineers move from digital design to a functional part in just days. No custom tools. No long waits. This shift has unlocked rapid prototyping, allowing automakers to test, iterate, and refine without sinking time and budget into each version.

For the industry, the payoff is speed and flexibility. Car companies can pivot faster, adapt to market demand, and even develop smaller production runs without blowing the budget. It’s leaner. Faster. More responsive.

Learn more about the 3D printing revolution

Customization at Scale

It used to be that custom features on a car meant a luxury price tag. Personalized grilles, unique trim, or a custom dash layout? That kind of detail was rare and expensive reserved for high end builds or aftermarket mods. But 3D printing is flattening the price curve.

Now, smaller manufacturers and even larger automakers are using additive manufacturing to deliver tailored components without driving up costs. Limited runs don’t require massive tooling or large inventories. If you want a set of interior panels in a rare texture or vents designed with geometric flair no problem. It’s just a design file and a few runs on the printer.

This shift lets automakers move away from the one size fits all model and into mass customization. It’s not about making millions of the same sedan anymore it’s about giving people options, personality, and small batch uniqueness at scale. Personalization no longer has to wear a luxury badge.

Sustainability and Waste Reduction

3D printing flips the script on traditional manufacturing waste. Instead of carving parts from blocks or stamping them from pre cut sheets, additive manufacturing builds parts layer by layer only where needed. That precision eliminates excess scrap, cutting down material waste from the start.

On top of that, the parts are lighter. In automotive terms, lighter often means better fuel efficiency. Shedding unnecessary weight translates into fewer emissions and better mileage, especially in electric vehicles trying to squeeze out every extra mile per charge.

Then there’s the big picture: a shift toward a circular economy. With 3D printing, damaged components can be remade or repaired without scrapping the whole. Manufacturers are also starting to explore eco friendly filaments and resins recyclable, biodegradable, or made from industrial byproducts. It’s not perfect yet, but it’s progress and a clear signal that sustainability isn’t just a buzzword. It’s being built into the design.

Supply Chain Disruption and Decentralization

3D printing flips the traditional auto supply chain on its head. Instead of warehouses full of parts, manufacturers can now store digital inventories just files on a server. When a part is needed, it’s printed on site or at a nearby facility. No need to wait on overseas shipments or maintain massive stockpiles.

Remote production is a game changer. All you need is a printer, the right material, and a design file. That’s enough to produce everything from brackets to bumper inserts. It speeds things up and slashes overhead tied up in shipping and storage.

This shift reduces logistics costs and softens the blow of global disruptions. It also hands more power to local shops and regional hubs. Instead of being last in line for parts, small facilities can print what they need, when they need it. It’s not just more efficient it’s more resilient.

3D printing isn’t just revising the supply chain it’s rebuilding it from the ground up. Explore how 3D printing is reshaping auto manufacturing.

Looking Ahead

The next frontier for 3D printing in auto manufacturing is scale. As printer capabilities expand and material costs shrink, printing large components even full vehicle frames starts looking less like science fiction and more like a production strategy. We’re already seeing concept prototypes with 3D printed chassis and structural parts. It’s early, but the direction is clear.

AI is quietly becoming a co pilot in this shift. It’s now shaping design from the ground up. Generative software can help engineers create smarter, stronger, and lighter structures that traditional CAD tools would never propose. These creations are tailor made for additive manufacturing complex geometries, minimal joints, and performance driven shape.

No, 3D printing won’t kill the factory. But it’s going to flip the blueprint. Instead of giant plants churning out the same component a million times, imagine regional hubs printing only what’s needed, when it’s needed. This isn’t a replacement it’s a rewrite.