Auto shops and home garages juggle delicate diagnostics, heavy components, and long hours on the floor. One minute, the task demands the precision of a benchtop; the next, it needs elbow-high leverage or a stand-up consult with a customer. Height-adjustable furniture closes that gap. It turns flat surfaces into tools that meet the job – reducing awkward reaches, keeping parts at safe angles, and cutting the stop-start fatigue that steals time from the day.

Well-selected systems also make tight spaces feel bigger. When a surface rises for layout and drops for storage, aisles clear and workflows stay smooth. The key is matching the mechanism to the job: robust platforms for mechanical work, refined motion for admin pods, and clean cable paths, so adjustments are quick and dependable.

Why Adjustability Belongs in the Garage

Shops live at the intersection of ergonomics and durability. Wrenching at the wrong height loads the lower back; soldering too low strains the neck. Adjustable platforms let techs stage components at wrist-neutral heights, then roll the same surface beside a lift for reassembly. Over a shift, small posture corrections add up – fewer awkward angles, steadier focus, better quality control.

Cleaning and safety improve as well. Surfaces that rise clear of sawhorses or carts are easier to sweep under. Wiring and air lines route cleanly when there’s a predictable travel path. In customer-facing areas, a sit-stand counter enables service advisors to seamlessly switch between screen work and face-to-face walkthroughs without needing to step away from their workstation.

The Anatomy of a Purpose-Built Work Surface

Not all adjustable platforms are equal. Mechanisms vary from scissor frames to column lifts, and the right choice depends on load, stroke, and duty cycle. For fabrication benches, parts staging, or detailing carts that require controlled vertical travel, a dedicated table lift provides smooth, straight-line motion that feels solid under weight. The best units combine quiet drive systems, rigid guide geometry, and simple controls that survive gloves, dust, and occasional solvent mist.

Surface selection matters as much as the lift. Hardwood butcher block damps vibration for small assembly. High-pressure laminate shrugs off chemicals and wipes clean. Edge profiles should be rounded – safer for sleeves and harnesses when moving fast. Mounting points for vises or clamps should be located in reinforced zones to prevent torque from being transmitted through the frame. When a bench doubles as a rolling island, lockable casters with wide tread keep movement smooth over expansion joints.

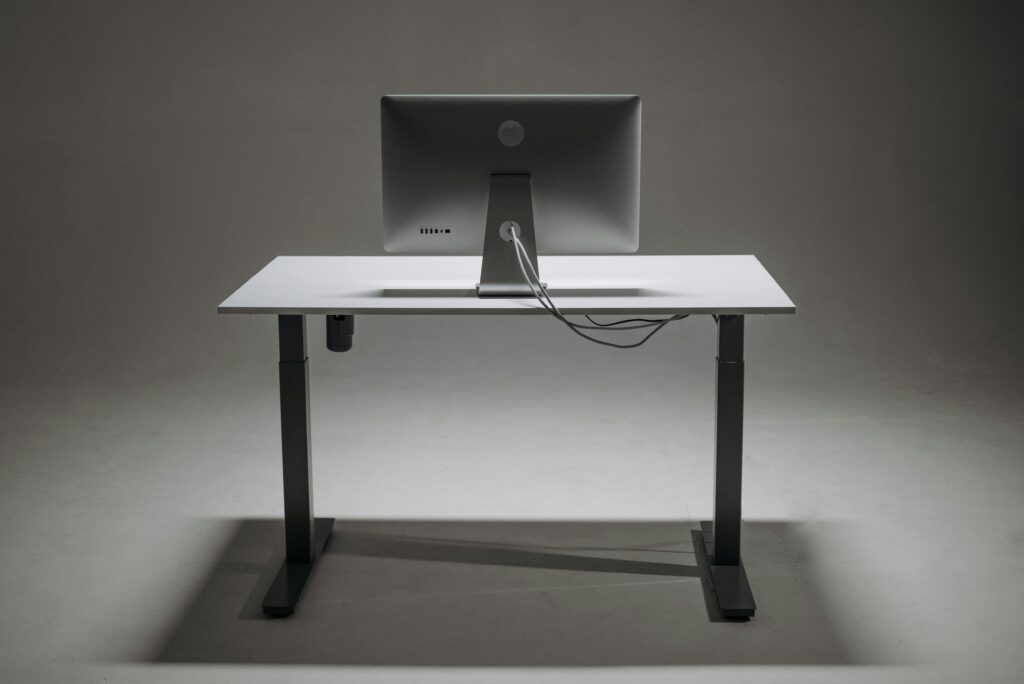

Choosing a Foundation for Screens and Admin Corners

Service bays aren’t only wrenches and torque specs. There’s scheduling, parts lookups, firmware flashes, and customer updates. A clean sit-stand station turns that administrative load into a quick pit stop rather than a posture trap. Starting with a reliable standing desk base gives the shop freedom to pair a rugged top with motors and columns designed for daily motion – think soft-start, soft-stop, and anti-collision logic that protects drawers and knees.

Look for three traits in busy environments. First, lateral stability at full extension, so typing doesn’t set up a wobble. Second, cable routing that moves with the desk – umbilicals or sleeves that can handle height changes without snags. Third, controller presets that make posture changes automatic; techs and advisors won’t use adjustability if it takes more than a tap between jobs.

Power, Safety, and Cable Management – A Quick Field Checklist

A tidy installation is safer, quieter, and easier to live with. One short list keeps adjustable benches and admin pods dependable:

- Plan one power entry per station – a surge-protected strip mounted under the top with slack for full travel.

- Use fabric sleeves or link chains for cords and air lines – leave gentle loops near moving hinges.

- Set collision sensitivity high in mixed spaces – drawers, carts, and pets don’t always announce themselves.

- Add a foot rail or anti-fatigue mat where standing is routine – small comfort, big compliance.

- Label controller presets by task – “Diagnostics,” “Paperwork,” “Assembly” – so height changes match real work.

These basics prevent the two most common headaches: snagged cables and mystery reboots from tugged plugs.

Workflow Ideas That Pay Off Fast

Staged teardown and rebuild. Raise a bench to shoulder height for a clear parts photo and labeling, then drop to mid-height for cleaning and inspection. Time lost searching for bagged fasteners drops, and reassembly becomes a straight path instead of a memory test.

Mobile detail cart. An adjustable island rolls beside the vehicle for claying, polishing, and protection steps. The surface rises to keep bottles and pads out of splash zones, then lowers for storage under a wall rack. Less bending, fewer spills, tighter turns around mirrors and pillars.

Programming nook. A compact admin pod near the bay switches from sit to stand during long firmware flashes. Screens set at eye level keep necks neutral while waiting on progress bars, and a quick tap brings the surface down for paperwork without rearranging a thing.

Customer handoff counter. A sit-stand front-of-house station meets clients at standing height for walk-arounds, then drops for signature and screen review. The change signals a shift from tour to task – clear, professional, and easy on the spine.

The Long Game: Durability Without Drama

Height-adjustable furniture earns its keep when it behaves like infrastructure – predictable, quiet, and ready every time. That starts with honest specs and continues with small maintenance rituals. Columns that lift within rated loads last longer. Fasteners that get a seasonal torque check stop squeaks before they start. Controllers programmed with soft limits protect walls, shelves, and window ledges.

The payoff is a shop that moves with its work. Benches rise to meet the hands doing the job. Screens float to the eyes, reading the data. Floors stay clearer, shoulders stay lower, and the day’s last task looks as tidy as the first. From robust table lifts in the bay to adaptable desk bases in the office, adjustable solutions turn square footage into flexible, human-friendly space – a quiet upgrade that shows up in throughput, accuracy, and how good everyone feels when the doors roll down.